Teamwork at scale for impact beyond border

Taylor, Texas, is home to one of the highest-profile construction projects in the US: a CHF 15 billion Samsung semiconductor plant. Sika delivered high-performance solutions from eight target markets to ensure material compatibility with a single source warranty.

The unassuming city of Taylor, located about 30 miles northeast of the state capital Austin, is known for its small-town feel, cornfields, and now vital role in bringing advanced manufacturing back to the US. Recent legislation has helped boost investment in strategic high-tech sectors. The government initiatives aim to not only boost the nation’s infrastructure, but also bolster economic resilience and tackle climate change. One tangible result is Samsung’s state-of-the-art semiconductor plant, which opens for business in 2024.

This immense facility spans 557,000 square meters and represents the first of ten phases of expansion. It will be well placed to respond to the expected growth in e-mobility and autonomous driving applications, along with other segments set to propel the semiconductor industry forward.

Thinking Big, Thinking together

Edith Somarriba is Sika’s Strategic Project & Account Representative who put the Project Team together and managed the project selling process. She recalls the early stages of a build that was complex enough to require five general contractors. “While working with the architect on the roofing, we first saw an opportunity to bring in our technical experts to answer questions about the transitions from the roof to the wall.” In addition to roofing solutions, Sika was soon entrusted with the technical recommendations for the installation of the facility’s critical electrostatic flooring – in addition to the waterproofing systems and concrete admixtures.

“We all stepped up to solve the customer’s problems together, which was only possible because of the team culture ingrained in us.”

“Once we showed the customer how we could help with multiple scopes of work, we were fearless in our approach.”

With just one point of contact on the Sika side, the customer also benefited from Sika’s synergistic approach and cross-selling strategy. Greg Luterman, Sika Roofing District Manager, Central Texas, believes Sika’s on-the-ground support proved crucial as well. “For roofing and waterproofing, we always gave the customer the tools to make the best decision, presenting several budget-conscious options based on their needs.” Sika teams also provided solutions that exceeded safety and sustainability requirements, including products with recycled content.

“We were able to bring in solutions to help every part of this building last – inside, outside, from the vertical to the horizontal. For me, this has been the project of a lifetime.”

At the heart of momentum

Customers recognize the value of Sika products that are not only quick to apply and dry, but also designed for site-specific needs. The flooring systems in the Samsung plant, for example, will prevent the build-up of static electricity – which could compromise components production, and even workplace safety. The rise in semiconductor plants, data centers, and electric vehicle, and battery production facilities will only heighten the need for specialized and experienced construction partners. For Jim Chilinski, Vice President Strategic Projects & Accounts, the Samsung achievement stems from more than Sika’s high-performance solutions.

“Our success in making the job of the general contractors, owner, and architects easier came down to our ability to build trust both inside and outside the Sika team. This is why the customer was as proud as we were and welcomed the Sika Board of Directors on site so they could visit this amazing project up close. That is the proof and power of unity.”

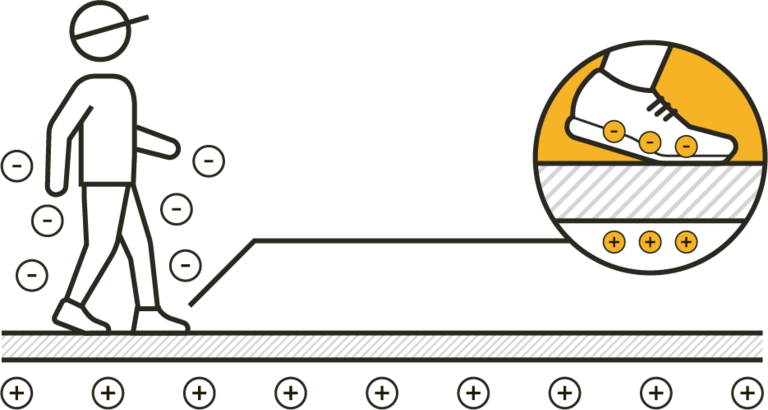

2. A separation of positive and negative charge occurs, and the person's body is negatively charged.

Challenge

- The negative charge associated with static electricity can cause electric shocks - typically felt at around 3,000 volts and visible as a spark at about 5,000 volts.

- Although the current strength may be low, static discharge poses a significant risk to microelectronic parts. They can be damaged or even destroyed by voltages as low as 100 volts. In addition, a spark from static electricity can ignite, potentially causing an explosion.

Solution

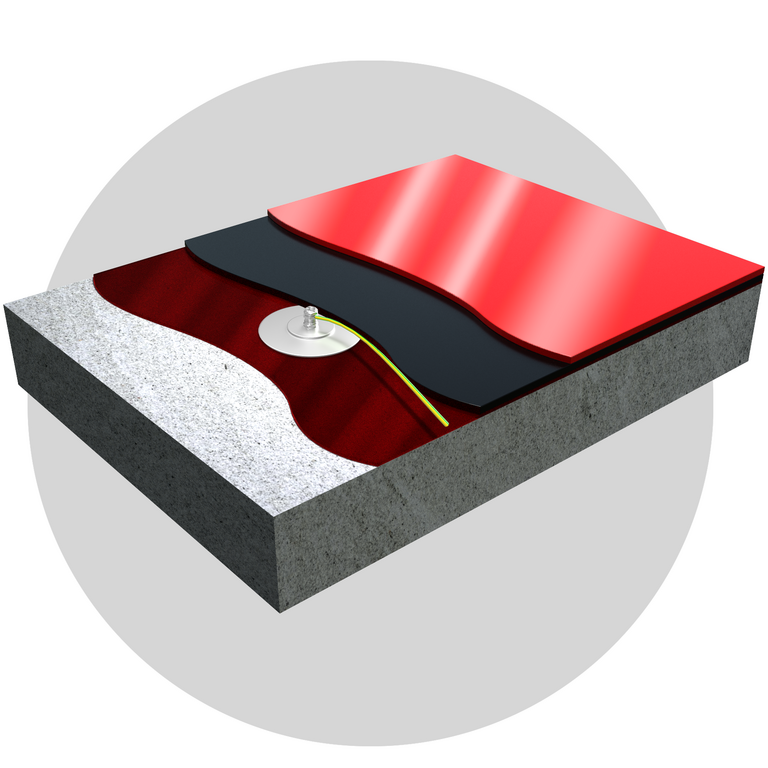

Sika conductive flooring

Sika's conductive flooring systems safely dissipate electrostatic charges, protecting individuals, eliminating the transfer of an unwanted electrical charge.

Innovation: Sikafloor®-2350 ESD

- Meets ESD-requirements even in low air humidity

- Low odor during application

- Meets the requirements of LEED V4

- High compressive strength and hardness

- Time and cost savings