Innovations Replacing steel reinforcement with macro-fibers

The World Business Council for Sustainable Development has selected Sika’s synthetic macro-fiber technology as a best practice for reducing scope 3 emissions. This technology replaces steel reinforcement in certain applications, thereby reducing carbon emissions.

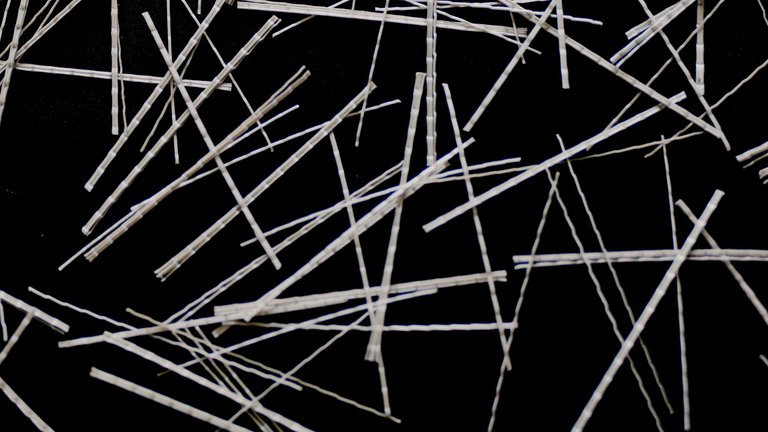

Synthetic macro-fibers are 30–60 mm long, and 0.4–0.9 mm in diameter. They increase the structural integrity and durability of concrete by distributing stresses or loads more evenly, thereby minimizing the incidence of cracking. “Macro-fibers offer a superior resistance against early and long-term cracking,” says Carsten Rieger, Corporate Market Development Manager, Target Market Concrete at Sika.Commonly used in slab-on-ground, precast elements, pavements and sprayed concrete applications, macro-fibers reduce the need for traditional steel-based reinforcement, resulting in improved safety, as well as cost and time savings.

Fibers to bridge cracks

Fibers are added to the concrete and mixed homogeneously to ensure three-dimensional reinforcing. When tensile stresses are applied to the concrete, small cracks begin to form. The fibers bridge the cracks, providing resistance to arrest further crack propagation. The fiber resistance provides additional load-carrying capacity in the concrete. Synthetic fibers are hydrophobic, which means they repel moisture. As a result, synthetic fibers do not corrode and perform well in alkaline environments. These attributes lead to higher durability and a longer lifespan of the concrete.

Saving time and costs

The use of macro-fibers saves time and costs in the construction process, by eliminating or significantly reducing the need for steel mesh production. Designed to reinforce slabs-on-ground, precast elements, and shotcrete applications, they are easily added into the concrete—either manually, at the batching plant, or via a conveyor belt into the mixer.

In shotcrete applications, they improve adhesion and reduce rebound (the material that bounces off the surface during spraying) by approximately 20% compared to conventional shotcrete, thereby minimizing material waste. A thicker layer of concrete can also be applied in a single step, which is more efficient.

In tunneling, mining, and slope stabilization, fiber-reinforced shotcrete also increases safety. Fibers can be dispensed automatically, allowing the concrete to be applied efficiently without the need for manual labor in hazardous or unprotected areas.

Once applied, the fiber-reinforced concrete is more flexible than traditional reinforcement, accomodating rock movements. Additionally, it can seamlessly follow the tunnel wall profile, allowing for more efficient placement with less material. “When using fibers, cracks that can appear in the concrete don’t endanger the construction. This is a major advantage because it allows early action to be taken,” says Carsten.

Optimized workability

The newly developed SikaFiber®-800 Stealth solution further optimizes workability. Due to low fiber memory, the fibers are less likely to protrude from the surface. This is important as more and more slabs are being installed without an overlay or coating.

With production facilities in the USA, Australia, Germany, Peru, and France, Sika guarantees the availability of macro-fibers worldwide. Carsten sees huge growth opportunities for fiber-reinforced concrete: “Increasingly, design codes are allowing the replacement of traditional steel reinforcements with fiber-reinforced concrete, boosting acceptance among engineers, contractors, and project owners.”

Selected as best practice for reducing CO2 emissions

As part of the Avoided Emissions Initiative led by the World Business Council for Sustainable Development (WBCSD), Sika’s synthetic macro-fiber technology has been selected as a best practice to reduce scope 3 emissions in the construction industry. The WBCSD’s Avoided Emissions Guidance is a critical tool for reconciling avoided emissions with globally recognized carbon accounting standards.